- Shed No-42, A-Block, D.S.I.D.C., Jhilmil Colony, Delhi - 110095, India.

What is a Weighbridge System and How Does a Weighbridge Work?

What is a Weighbridge System and How Does a Weighbridge Work?

You might have seen industries like transportation, logistics, mining, manufacturing, etc. using a special type of platform scale to measure the weight of an entire vehicle. They are in fact using weighbridges to ensure their vehicle-driven operations run smoothly and without any safety or compliance issues.

A Weighbridge (also known as a truck scale or vehicle scale) is a large, heavy-duty scale used to weigh vehicles and their contents, such as trucks, trailers, or containers. It is typically installed on a solid foundation, allowing vehicles to drive onto the platform to be weighed.

In this blog post, we’ll explain what a weighbridge system is, how it works, and why it’s essential for industries that require accurate weight measurements. We’ll also highlight Essar Weigh, a leading provider of weighbridge solutions.

Also Read Us: Top 10 Weighbridge Manufacturers in India

What is a Weighbridge System?

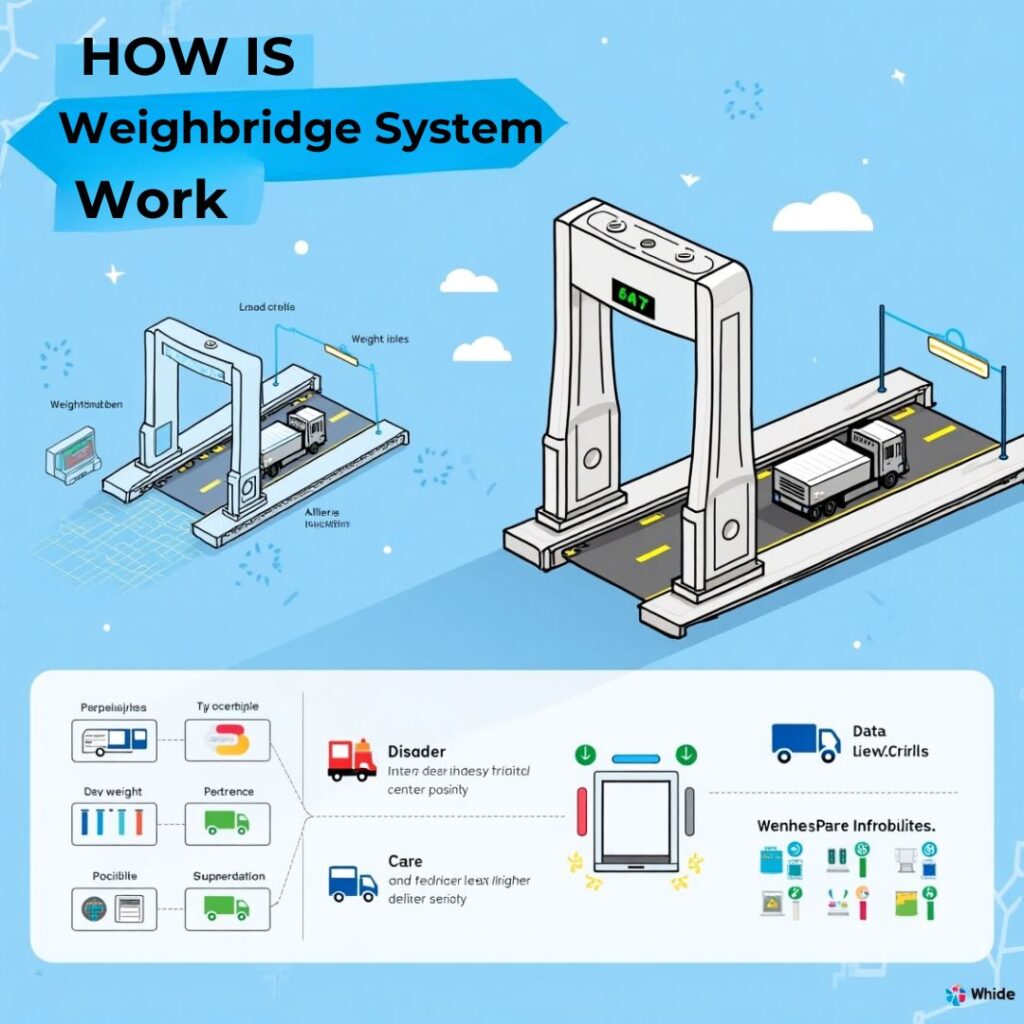

A weighbridge or a truck weighbridge scale is an instrument used to weigh very heavy loads carried by vehicles. This scale consists of a robust steel or concrete platform, a stable foundation, a weight terminal indicator, a junction box, a weighbridge controller, and some load cells/sensors. These systems are typically used in places like factories, distribution centers, warehouses, ports, and construction sites. The system comprises a platform, load cells, indicator, and software to provide accurate weight readings.

The weighbridge can be either pit-mounted (embedded into the ground) or deck-mounted (sitting above the ground), depending on the installation requirements. The system helps businesses monitor cargo loads, ensure compliance with legal weight regulations, and optimize logistics operations.

How Does a Weighbridge Work?

Weighbridges operate through a simple process that combines mechanical and electronic systems. Here’s how the weighing process works:

1. Vehicle Drives onto the Weighbridge Platform

A vehicle enters the weighbridge system, either by driving over the scale in the case of a deck-mounted weighbridge or into a pit if it’s pit-mounted. The vehicle is placed centrally on the weighbridge platform.

2. Load Cells Measure Weight

Underneath the weighbridge platform, there are load cells (electronic sensors) that measure the weight of the vehicle. These load cells work by detecting the force exerted on the platform as the vehicle is placed on it. The weight data from these cells is transmitted to the indicator for processing.

3. Weight is Displayed and Recorded

The indicator, which is a digital display or computer system, processes the data from the load cells and displays the weight of the vehicle. The weight reading is accurate, reflecting the total weight of the vehicle and any load it may be carrying.

4. Data Processing and Reporting

Weighbridges often come with software that records, stores, and generates reports of the weight data. The software can be integrated with other systems to track vehicle movements, monitor load consistency, and generate reports for compliance purposes.

5. Exit and Repeat

Once the weight has been recorded, the vehicle can exit the weighbridge, and the system will automatically store the reading. If needed, the process can be repeated for vehicles returning with different loads, ensuring accurate weight tracking.

Types of Weighbridge Systems

There are several types of weighbridges to meet different operational needs:

- Pit-Mounted Weighbridges

These weighbridges are embedded into the ground and are ideal for high-traffic areas where vehicles frequently pass over them. - Deck-Mounted Weighbridges

These are placed above the ground and are typically used in areas where excavation for pit mounting is not feasible. - Mobile Weighbridges

These weighbridges are portable and can be relocated to different sites as needed. They are useful for temporary setups. - Axle Weighbridges

Axle weighbridges are designed to weigh individual axles or groups of axles rather than the entire vehicle. Axle weighbridges are commonly used in industries such as mining and construction, where it is important to ensure that individual axles do not exceed weight limits.

Why Are Weighbridge Systems Important?

Weighbridge systems offer several benefits to industries that rely on accurate weight measurement:

- Compliance with Regulations

Many countries have legal weight limits for vehicles on public roads. A weighbridge ensures that vehicles do not exceed these limits, helping businesses avoid fines and penalties. - Operational Efficiency

By accurately weighing vehicles, businesses can optimize load capacities, avoid underloading or overloading, and improve transportation efficiency. - Inventory and Resource Management

Weighbridges help businesses track the movement of goods, ensuring that they have accurate records of incoming and outgoing shipments. - Cost Savings

Weighing vehicles ensures that companies do not overpay for transportation costs or incur unnecessary fines for exceeding weight limits. It also helps in optimizing resource usage and reducing operational overhead.

Why Choose Essar Weigh for Your Weighbridge Systems?

At Essar Weigh, we are dedicated to providing high-quality, reliable, and durable weighbridge systems for various industries. With years of experience in the field, we offer customizable weighbridge solutions designed to meet your specific requirements.

Here’s why Essar Weigh should be your go-to provider for weighbridge systems:

- State-of-the-Art Technology: Our weighbridge systems are equipped with the latest technology, ensuring accurate weight measurements and seamless integration with your existing systems.

- Durability: We offer robust, long-lasting weighbridges that can withstand harsh environments and high-traffic areas.

- Customization: We understand that every business has different needs, which is why we offer tailored solutions to fit your specific requirements.

- After-Sales Support: Our team provides comprehensive after-sales support, including installation, maintenance, and troubleshooting services.

- Compliance: Our systems are designed to help you stay compliant with all legal and regulatory weight limits, ensuring smooth operations.

Conclusion

A weighbridge is an important piece of equipment that is used in a vast variety of industries. It is a large scale that can weigh vehicles with or without their loads. This instrument uses load cells to convert the force applied by the vehicles into electric signals giving you an accurate estimate of their real weights. Whether you’re in logistics, construction, agriculture, or any other sector, a reliable weighbridge system is crucial for ensuring efficiency, compliance, and cost management.

At Essar Weigh, we provide top-of-the-line weighbridge systems that deliver accuracy, reliability, and durability. Choose us for your weighbridge needs and streamline your operations today!